#Cnc simulator apk software#

This software has been around since 2011 and is popular among hobbyists.

#Cnc simulator apk free#

You don’t have to splash out to benefit from CNC simulator software – CAMotics is one of several open-source simulator solutions that are completely free to use. Best Free CNC Simulator Software CAMotics – Powerful yet user-friendly free CNC simulator We take a look at both in this guide to help you find the perfect match for you – let’s get into it. There is a wide range of different solutions on the market, including simple software designed for beginners and highly advanced, complex software for CNC professionals. However, the issue with these is that they often don’t accept already programmed G-code, which is why many people seek out specific CNC simulating software. Most specialist CAM software have simulating capacity built-in.

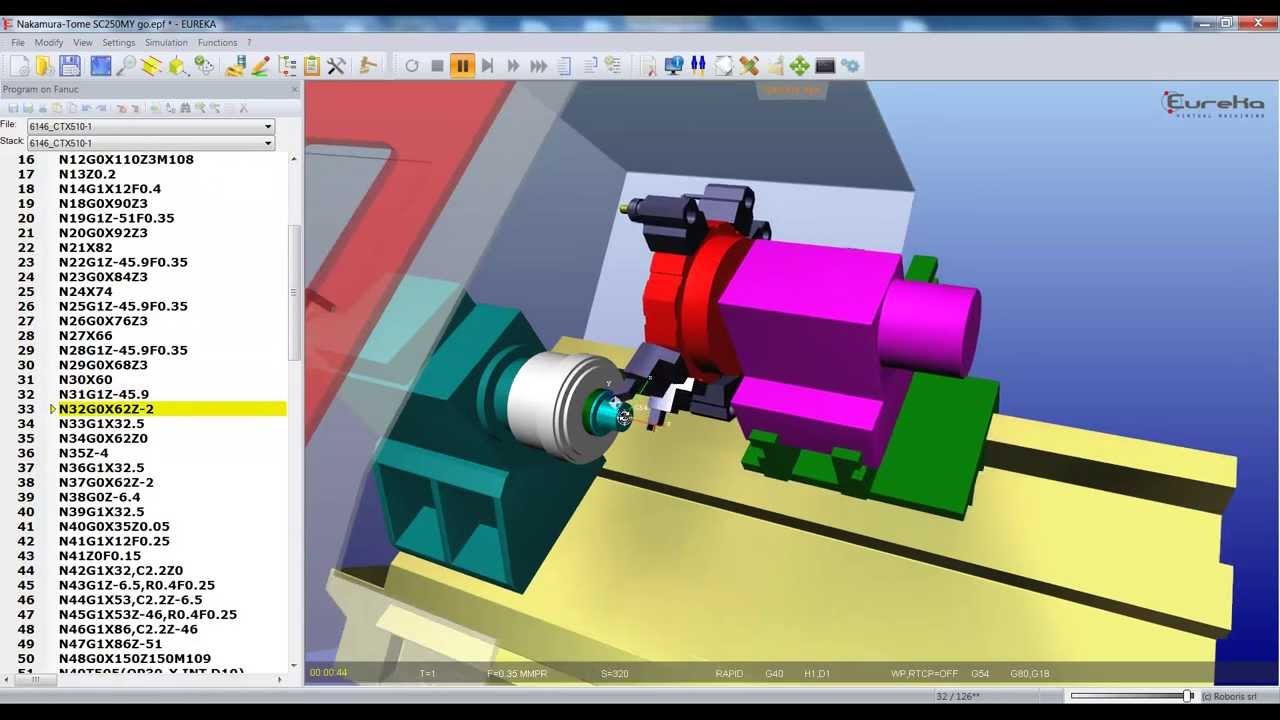

For example, some allow you to write and edit G-code, while others have built-in CAM and CAD capabilities. While simulation is the essential use of CNC simulator software, many programs offer other capabilities. Most simulator programs can be used to simulate operations for a range of different machines, ranging from CNC routers, mills, and lathes to laser cutters, water jets, and 3D printers. Another benefit, and one that’s particularly relevant to the current COVID era, is that they allow CNC students and professionals to train and work remotely. With a simulator, you can gain insights into how the overall CNC process can be improved and optimized, without wasting any material making real-life mistakes.ĬNC simulators are often used in schools and colleges for educating students, as well as for training staff in businesses.

This means that not only does a CNC simulator help achieve more accurate machining, but it also makes the process more efficient by helping save time and cash as you won’t need to waste money on replacement workpieces. First and foremost, it allows you to test G-code for inaccuracies and errors without the risk of damaging a workpiece. There are various benefits of using a simulator. Simulators are often referred to as the ‘digital twins’ of real-life CNC machines. With simulator software, you can simulate G-code operations and then visualize the results in 3D. Once you’ve read this guide, you can also read our guide on the best CNC software The Basics of CNC Simulator SoftwareĪ CNC simulator is a way of simulating G-code and toolpaths to predict the behavior and outcome of machining processes. But what are the best CNC simulators? That’s exactly what we reveal in this guide, where we rank the best CNC simulator solutions for different niches, including both free and paid software.

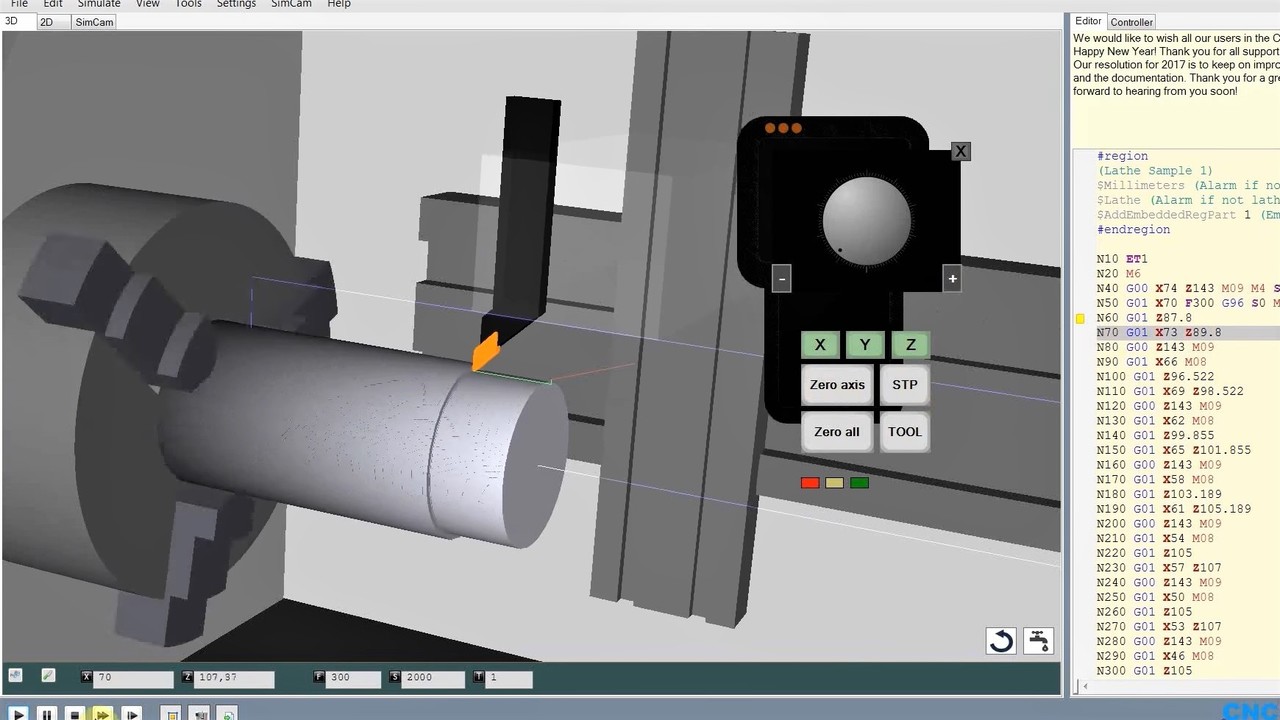

To help achieve this, many hobbyists, students, and professionals use CNC simulator software.Ī CNC simulator is an invaluable tool as it allows you to test run projects without the risk of damaging or incorrectly marking a workpiece. Even a small error could potentially wreck a project, which is why it’s always important to make sure you’re as best prepared as possible, whether you’re using a CNC router, laser cutter, or any other type of machine. The functionality of the simulator: preparation of texts of control programs of turning operations in the format of a standard GM code, checking control programs for syntax and technological errors, playing on the computer screen (or other computing device) three-dimensional graphic models of the main components of the lathe machine and metal-cutting tools to simulate the process of turning metal, the three-dimensional visualization of the process of forming parts during turning on the compiled control programs, visualization of toolpaths, implementation of interactive user interaction with the simulation model of technological equipment.In CNC machining, precision is key. Material processing is performed on two axes in the horizontal plane.įield of application of the software product: educational process using computer technology: laboratory lessons of students in computer classes, distance learning, demonstration support of lecture material in the group of areas of training and specialties: «Metallurgy, Engineering and Material Processing». The basis of the three-dimensional simulation model is a lathe with a classical arrangement of units, equipped with a CNC system, an eight-position turret, a three-jaw chuck, a tailstock, a coolant supply system and other machinery.

#Cnc simulator apk code#

A software simulator of a numerical control (CNC) lathe is an educational methodological development intended for basic familiarization of novice machine building specialists with the principles of programming parts turning operations using standard GM code (Fanuc System A).

0 kommentar(er)

0 kommentar(er)